FORTNIGHT ISA MULTIMEDIA DOCUMENTARY PROJECT ON THE MILLENNIAL GENERATION: THE LAST GENERATION TO REMEMBER A TIME WITHOUT THE INTERNET. |

typeface

typeface

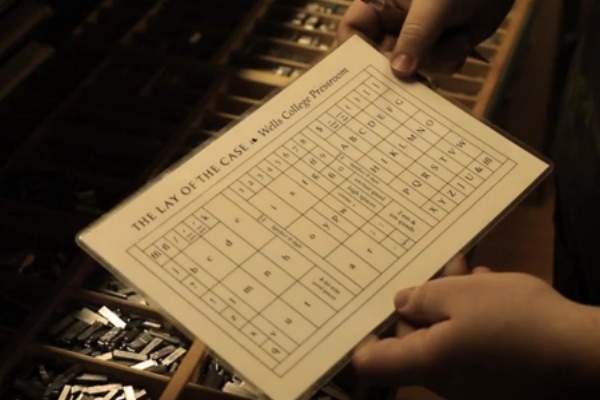

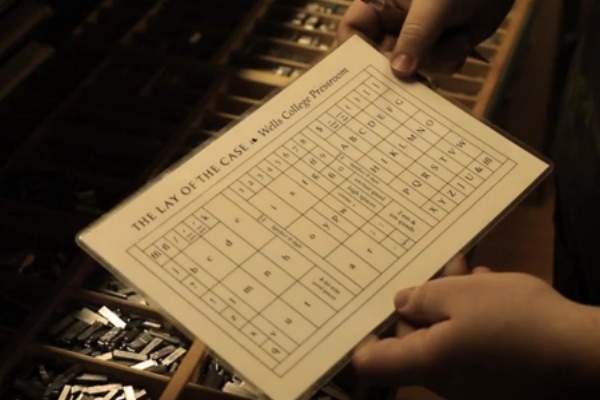

WE SAY UPPER AND LOWER WITHOUT KNOWING

THE TRUE ORIGIN. ROB EXPLAINS THE CASES.

watch the video now >>

WE SAY UPPER AND LOWER WITHOUT KNOWING

THE TRUE ORIGIN. ROB EXPLAINS THE CASES.

watch the video now >>

|

Throughout the 19th century, one of the main problems still troubling the field of printing was the time involved in setting type by hand. While press and paper making machines had become automated, type still needed to be set by hand and then put away by hand after printing.

Mark Twain invested most of his fortune in the Paige Compositor, an automatic-typesetting machine |

|

invented by James Paige in 1872. Unfortunately, the cumbersome machine never worked satisfactorily, and Paige died penniless. The true breakthrough would come once a machine that could both set and cast type was invented. First though, a way was needed to mass-produce the mats, or molds for the letter part of a piece of type. In 1885 the American Linn Boyd Benton invented the pantographic punch cutting machine. This invention revolutionized both type design and casting. Punches and mats could now be mass produced. Skilled punch cutters were no longer needed, and type design moved from the art of engraving steal punches to drawing letters on paper. With the ability to make an almost unlimited number of mats, the scene was ripe for an entire system that could not only set freshly cast type, but be mass-produced. The answer came in 1886 when Ottmar Mergenthaler, inventor of the Linotype machine, produced his first commercial model. In 1890 the Mergenthaler Linotype Company was founded in Brooklyn, NY. Unlike the Paige Compositor, the Linotype was incredibly successful. By 1892 over 1000 Linotype machines had been produced, and are still considered to be among the most complex machines ever mass-produced. |

Entire lines of type were cast on a single body, hence the name "Line-O’-Type." By eliminating both the needs for hand setting and distribution, the type dilemma seemed solved. Printed, it was simply melted back down and recycled. At roughly the same time in 1887 Tolbert Lanston patented another mechanical typesetting system, Monotype. Unlike Linotype, the Monotype system was separated into two separate machines, a keyboard and a caster arrangement inspired by the player piano. The operator keyed text into the keyboard that would perforate a paper tape. The paper tape could then be run into a caster that read the holes and cast the desired type. Unlike the Linotype where mats are dropped down into a line and were then put away, the Monotype arranges the mats in a set grid pattern. Each letter is assigned a set of coordinates and the caster moves the mats above a stationary mold. Additionally, the Monotype system cast and set individual pieces of type, rather than lines, making corrections easier. The Monotype system, though slower than Linotype, overcame many of the technical limitations of Linotype, and was easily adapted to foreign alphabets, accented characters, and setting mathematics. Having the keyboard separate from the caster also allowed keyboarding to be done off |

|

site, even in an office setting, and then the paper tape could be sent out for casting. The invention of the Linotype and Monotype machines were the crowning achievements in letterpress technology. Now type, paper, and print could be mass produced and distributed. Surprisingly, the new technology would also result in a revival and interest in older printing.

*** Rob LoMascolo began studying letterpress and book arts at Wells College, in Aurora, NY. There he studied with Terry Chouinard, Herbert Johnson, Mark Argetsinger, and Michael Bixler. He received an MFA from the University of Alabama. He is currently a freelance letterpress and book arts artist in Union Springs, NY. Some of his clients included The Frick Collection, members of the Grolier Club, Wells College, private book collectors, and conservators. |